Posts Tagged ‘aa4oo’

Begali Intrepid

Begali Intrepid

The Perfect Bug?

A New Design

- The pendulum hinge is at the rear of the key rather than the middle

- The adjustments are all based on magnets rather than springs

- The dwell for the dits has a real control, rather than using various pieces of foam, string or clips to change dwell time

- The dit contact is a sprung plunger that always remains centered on the contact rather than brushing against it at various angles

- The split lever mechanism operates at the center of the key placing the DAH and DIT contacts much closer to one another than a traditional bug

- There is less mass in the pendulum itself than a Vibroplex Bug

- It has a sprung, nylon wheel damper that doesn't clatter

- It weighs a TON (well about 6 lbs) and feels welded to the desk without having to use non-slip material or using spit to semi glue them in place (yech, yes I use spit to hold my keys to my desk)

Preparing for Use

In Use

Conclusions?

The Endurance of CW in Amateur Radio

The Endurance of CW in Amateur Radio

CW Spans a Century

What other modes have remained as popular standards using standard ham equipment and continuously in use by amateur radio operators as CW?

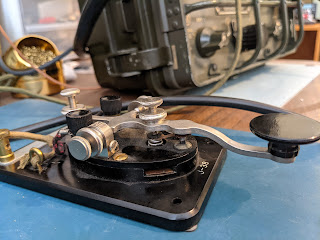

AN/GRC-9 aka “Angry Nine”

AN/GRC-9 aka “Angry Nine”

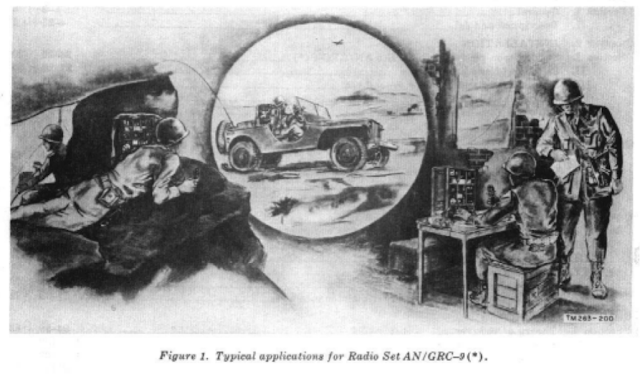

AN/GRC-9 - Long lived military comms

|

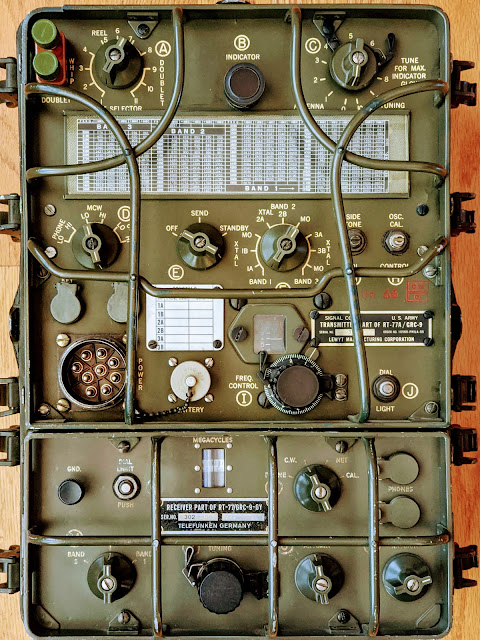

| My lovely (and radioactive) RT/77-GRC/9 |

|

| Hot receiver, in more ways than one |

|

| Out of the case, tracing a low B+ power problem |

Power on the move

- Transmitter Plates -- 475 - 580 v @ 100ma

- Transmitter Filaments -- 6.5 - 6.6 v@ 2 amps

- Receiver Plates -- 105 - 120 v @ 45ma

- Receiver Filaments -- 1.35 - 1.5 v @ 500ma

- Keying Relay -- 6.0 - 6.9 v @ 575ma

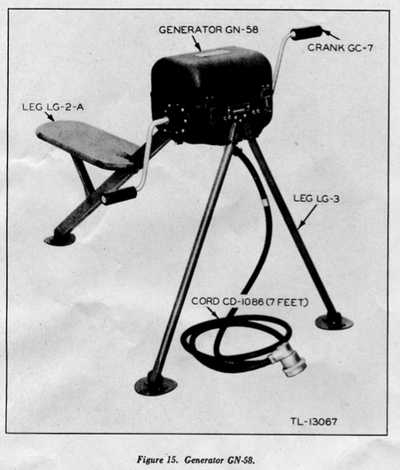

That's a tall order for mobile and portable power supplies but designers in the 1940's were quite clever in packing power supply units. I managed to obtain both the hand cranked GN-58 generator with the base chassis and seat for portable operations, and a DY-88 for fixed / mobile operations.

DY-88 mobile power supply

| DY-88 set to 12v powered by Amateur 12v supply |

|

| Vibrator power supply for low B+ |

|

| Power filtering |

I supply the DY-88 from either an RV battery or an amateur 12v power supply. When in Standby the DY-88 draws less than 1 amp, but placing the radio in Send mode switches on the Dynamotor which draws 12 amps @12v, without key-down and up to 14 amps on high-output key-down. It will drain an RV battery pretty quickly at that rate if the radio is left in Send mode, and works an amateur power supply pretty hard as well. So don't expect to operate remote off a battery alone for too long if your having lengthy QSOs. An added benefit of the DY-88 is that when the enclosed Dynamotor is running you'll have a nice extra 85 dB of generator noise to accompany your listening pleasure.

GN-58 portable field hand-cranked power supply

|

| Generator head in carry bag |

|

| NOS Shiny |

|

| Deployed |

If you have a BC-48 battery hooked up then your human power supply can pause cranking while your receiving. I have a BC-48 battery enclosure that has been gutted of the original, long-dead material and replaced with 10x 9v batteries in series for the low B+ and two D-Cell batteries in parallel for the receiver filament supply.

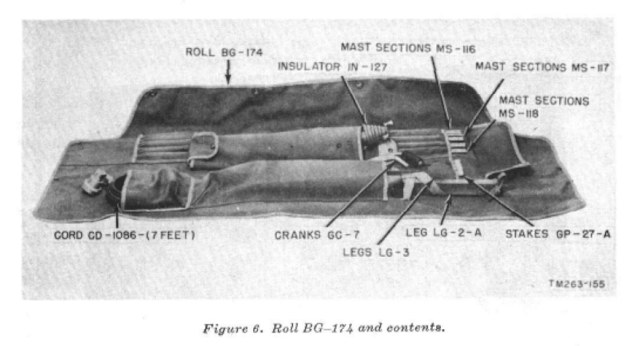

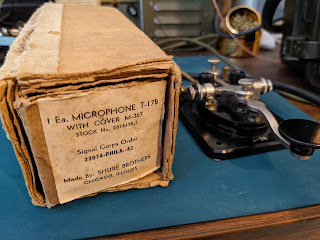

Accessories

|

| Bag of goodies |

Headphones

|

| Homebuilt CW filter with impedance switch |

Speaker

Antennas

Spares

More to come

|

| 50 kHz spacing when reading the frequency on the receiver Note the 7.2 is 7.200 MHz in the 40m band |

Images

Notes

Instructions for restoring a vibrator to operation

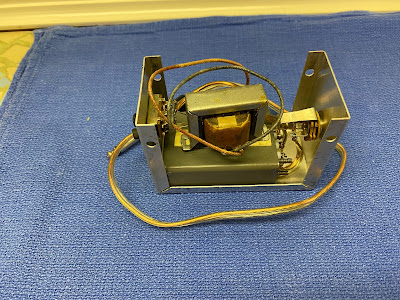

Regulated voltage for Regenerative receiver project

Regulated voltage for Regenerative receiver project

Mr. Regula-tor

Fortunately, the regen circuit uses a ridiculously small amount of current for B+; about 4 to 5mA. Although I will likely change the audio side of the tube to deliver enough current for a speaker rather than the high impedance headphones in the current design, which may potentially double that to 10ma. For the first incarnation I'll stick with high-impedance headphones.

Generally batteries are used with regenerative receivers because they are so sensitive to power supply noise, but I wanted to give the power supply a shot first and if it proves too noisy I can fall back to battery power for the B+ and just use the filament voltage provided by this transformer.

Since I have a OB2 voltage regulation tube I want to use. The OB2 regulates at 108V so that's what I'm going with. An OB3 would regulate at 90V, but I don't have one of those.

|

| OB2 in action... Glow baby, Glow! |

Calculating the resistor drop

Rdrop = (Vs - Vreg) / (Ireg + Isupply)So, in my case:

Voltage supply (Vs) = 189V

voltage regulation (Vreg) = 108V

regulator current (Ireg) the OB2 requires 5mA to do its job = 5mA

supply current (Isupply) the actual current required by the 6SN7 up to ~ 5mA

So, (189V - 108V) / (0.005A + 0.005A) comes out to a resistor value of 10,100 ohms. 10k is the closest standard size resistor and at 108V it should be able to dissipate 1.166 watts. So I'll need a 10k 2-watt resistor.

Parts is parts

Summary

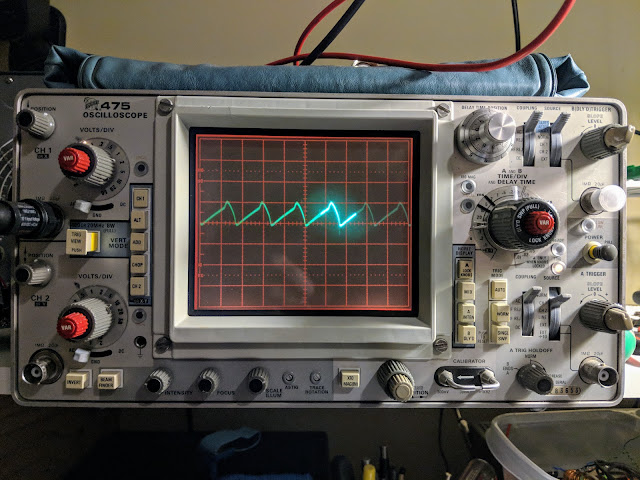

With the current values I'm seeing 50mA ripple on my regulated voltage.

|

| A bit over 50mA ripple |

That's all for now....

So lower your power the old fashioned way, using a voltage regulator tube.

72/73

Richard, AA4OO

Metering High Voltage on the cheap

Metering High Voltage on the cheap

🗲 Heathkit VTM model IM-11 🗲

So what did hams of yesteryear use?

Behold... Vacuum Tube Volt Meter

Vacuum Tube Volt Meter

This Heathkit VTVM model IM-11 was available at my local Hamfest (Rarsfest) for 5 dollars.Debugging

The 55 year old 16uFd@150V paper, electrolytic power filter capacitor was likely a ticking time bomb so I replaced it with a modern capacitor for safety concerns. The closest one I had was a 33uFd@160V radial electrolytic. I don't think double the capacitance will be a problem for a filter capacitor, it will just make the transformer work a little harder when it's first turned on. I calculated the initial charge time and it's 393ms vs 190ms for the original cap. I think the 10k resistor and transformer can handle the extra 200ms heavy load on power up.

A few wires inside the meter had come loose from some very sparse solder points and a one intermittent connection in the range switch was especially troublesome to track down.

The biggest mystery to solve was oversensitive resistance readings in the Ohms mode. I replaced the C-cell battery in the battery cup and while I had it out I glanced at the + connection for the battery in the cup. I appeared to have oxidized at some point in the past and was discolored. I scraped it off until I saw shiny bits and thought all was good. I spent more time tracing the circuit and thought I had a problem with the switch itself or the 9x resistors in the range circuit, as suggested in the troubleshooting section of the manual. The problem turned out to be that oxidized bolt head that formed the positive battery connection in the battery cup. Scraping it had not provided electrical contact. In fact, when I removed the bolt (after having to disassemble the circuit board from the meter for the 2nd time), I filed down the head of the bolt and could find no conductive metal left. I'm guessing that a former leaky battery had converted the entire head of the bolt to a very hard, yet non-conductive material. I've never seen anything like it before and it proved to be a useful lesson.

I had to find a replacement bolt and that lead to working on my lawn mower and then mowing the yard... not sure how that progression occurred... Eventually I got the new bolt in the cup, the circuit board re-installed. Ohms tested accurately, put it all back together and noticed the #50 pilot lamp had stopped working (sigh). I removed the innards from the case one more time and got the pilot bulb settled (I think it's required to balance the filament circuit). While I had it apart for the umpteenth time, I decided to reconnect the 1/4" plug that a former owner had disconnected while keeping their original modification allowing 1 mega-ohm to be switched in for the outermost probe when DC functions are selected but switched out when AC or Ohm functions are chosen. I wanted to allow use of an original VTVM probe used in the 1/4" plug with its built-in 1 mega-ohm resistor.

Whew!

All-in-all, I probably spent 8 hours getting all the functions on my $5.00 meter to work, replacing old parts, undoing mods and aligning it for proper DC and AC readings. It's a good thing I don't count my time in the cost of these projects, otherwise I could have purchased a couple Fluke meters for the cost of my time.

What's the fun in buying something that works right the first time when you get it home, huh? Are we hams, capable of solving problems, or appliance users? Actually, it would have been nice if it worked without new parts and repairs, but I digress.

Back to the story

This meter can measure up to 1500 Volts 🗲

Although this meter uses a C-cell battery for measuring resistance, it runs off service mains to power the tubes which control the meter circuitry, so it must be plugged in to be used.

Wiring, lots of wiring

|

| Point to point wiring makes for interesting circuit tracing |

Shiver me timbers, it's got decks

It also refers to "front half" and "rear half". The "half" is referring to a side of the deck, so in the case of "front half" it refers to the side of a particular deck facing the front of the instrument, while the "rear half" is the side of a deck facing back (or toward you).

|

| Clever voltage divider circuitry, what could possibly go wrong in this triple stack of wafer switches? |

A knob for every function and a function for every knob. NOTE: do not plug your headphones into the 1/4" jack on the front unless you want to experiment with personal electro-shock therapy. Better, yet, don't plug your headphones in there.

|

| Not clearly shown in this photo, voltage divisions up to 1500 volts supported |

"...Weighed in the scales and found wanting"

Summary

Dazzle your friends next time they ask you to measure something for them, by whipping this not-so-little-puppy out of your back pocket and powering it up. As you're making your measurements quietly repeat "Mmmm, yes. Mmmm yes, I see now". They'll have no idea what you're referring to and be quite impressed.

Remote VFO – Knight V-44

Remote VFO – Knight V-44

Everyone needs a remote VFO from 1955

The 1955 remote VFO was unique because it had a built-in power supply. It's also interesting that its base oscillation frequency is in the 160m band. Using harmonics from the base frequency means it doubles for each subsequent band (x2 for 80m, x4 for 40m, etc.) That doubling means it also multiplies the drift. Specified drift is 300Hz an hour. That doesn't sound too bad, but multiply that by x6 up in the 10m band and holy-smokes, it's drifting 1800Hz an hour.Note to self: Never browse eBay just before you go to sleep

That's gonna make operating CW like a game of chase, or hide and seek after every exchange.

This is gonna be fun.

|

| Surprisingly the big dial is actually operating the variable cap through a reduction gear and it's very smooth |

|

| Uses 4 tubes. Power supply up top, VFO circuits in the bottom to minimize impact of heat from the PS. |

|

| Power supply |

|

| old electrolytic power filter cap must be replaced |

|

| 10k 7watt resistor had failed |

Replacement bits

The 450v electrolytic cap must be replaced for safety reasons. All the other components measured within 10% of specifications except for the 10k 7w resistor connected to the OA2 tube. It had gone up into mega ohms of resistance, which is likely when the VFO was taken out of use.Handwritten notes inside the chassis indicated the VFO tubes had been replaced in 1977. Until I get the replacement parts for the power supply I won't know the condition of the tubes.

Plans

Surprisingly, it outputs 10 volts of signal, so I may also build an output filter and use it as a QRPp transmitter on its own.

The possibilities are endless.

Update 3/21

Repaired

The replacement parts arrived from Mouser... A 500v 47uF electrolytic capacitor and a 10k Ohm 7-watt resistor. The new high wattage resistor is tiny compared to the giant, defunct resistor that was in there before, and of course the capacitor was about 1/3rd the size of the original. I used some spaghetti on the capacitor leads since the lead lengths were so much longer with the replacement cap. So the power supply section was now repaired.I also replaced the 2-blade, non-polarized, ungrounded, un-fused 1950's power cord with a 3-pin grounded plug and added a 1-amp/250v inline, replaceable fuse. So hopefully there's a reduced risk of death or fire now. Electrical safety didn't seem to be foremost on the minds of kit builders 60 years ago. The size of the 3 wire power cable and it's much thicker insulation didn't fit the opening in the back of the VFO as both the power cable and the VFO output come through the same hole, so I had to remove the insulation and use heat shrink to get things to fit. Additionally the large in-line fuse holder didn't fit well inside the VFO housing so the wiring is quite a bit more cramped in there than it was before.

After the components were replaced and the wiring was complete I plugged it in... no-smoke. Then I flipped the repaired switch (the phenolic disc for the on-off switch was broken in half when I received it), and wallah! The indicator light lit up through its pretty little blue jewel eye. So I knew the transformer was supplying 6.3v for filament. I heard a low hum from the little transformer and then the tubes began to glow. The OA2 was glowing it's pretty violet color, and no bad smells were emanating. I was ready to button it up and begin calibration.

The sparse instructions directed me to back out the tuning slug for the 80m band nearly to the end and screw in the slug for the other bands all the way, so I did so. I set the trimmer caps C1 and C2 to their fully engaged positions.

I carefully re-installed the front face holding the VFO and PS sections it in its heavy-duty case, taking care to get all the new power cord/fuse wiring inside the VFO section from binding up on the sharp edges of the case as it went in. In screwed in the plentiful 10 screws that holds it together and Bob's your uncle. Well, maybe Bob isn't your uncle but I just wanted to say that.

I had already attached an RG-58 coax to the output inside the VFO and run it out the hole with the new power cord, so I then installed a BNC connector on the end of the RG-58 to make hookup easy. I like BNC connectors because they are secure and I have lots of adapters for different connectors. I then connected the VFO output to my Elecraft CP1 RF coupler and terminated the other end with my ugly dummy load. I connected the RF coupled cable to the Oscilloscope and turned everything back on.

Calibration

I let it warm up 20 minutes or so. The cabinet does not get very warm, just about 15 degrees above room temperature. That's actually a good thing, from what I've read. If the VFO is at room temperature then it's more susceptible to the variations of that room temperature. Having the case stabilize above room temp can make the VFO more stable.I had my frequency counter attached to an output from the oscilloscope. In the 80m band setting with the VFO dial set to 3.5 Mhz the freq-counter was reading around 1.75'ish. The VFO primary oscillation roams around the 160m band and generates the first harmonic in the 80m band. The freq counter had trouble tracking due to all the harmonics, and the output on the oscilloscope was not very pretty because it was showing the primary frequency with the first harmonic interfering.

I was unable to properly calibrate the VFO using a frequency counter, due to the interference from the harmonics, so I turned on my SDRPlay, software defined radio. It can display up to 10 mHz bandwidth but for this test I was displaying 2 mHz bandwidth so that I could easily see the harmonic for the band I was calibrating.

That made quick work of calibration. I adjusted the variable capacitor C1 (near the bottom left hand side of the VFO) for the 80m band and adjusted the one above it for the remainder of the bands. I was able to verify that adjusting the VFO dial in the CW portions of the bands was extremely accurate with regard to frequency.

It appears to work like a charm. I hooked up a key and even sent some test messages and listened to them on the SDR. I'd been advised to not key the VFO directly because it tended to chirp but frequency stability was much better than I expected. Over the course of an hour that I was calibrating I saw very little drift after the initial warm-up.

Here's a little video demonstrating the completed calibration...

That's all for now .

So, warm up your Tubes and spray some RF into the air.

73

Richard ,AA4OO

Need a Vacuum Tube?

Need a Vacuum Tube?

Superstore for Vacuum Tubes

So if you've been looking for a good source for all your classic vacuum tube needs visit...