Here we go again………

Here we go again………

September last year I had an issue with my Icom 7610, it was shutting down and restarting. The issue was a supply low voltage situation. With the 7610 if the incoming voltage drops below 11.44 volts the radio turns off. This voltage drop happens during transmit (CW in my case) then the radio cycles off, the current draw stops and the voltage goes back up and the radio cycles back on again. This is a normal situation with the 7610 and is supposed to happen with a voltage drop at or below 11.44 volts DC. In my last post when this happened in September 2022 I narrowed it down to the Anderson power pole connectors for more details click the "In my last post link above.

On Wednesday I was taking part in the 1-hour CWops mini contest and out of the blue while transmitting my 7610 cycled off and then on again. I thought "Here we go again". I had a good idea where the problem was and to finish the contest I lowered my power from 100 watts to 50 watts. I have the Astron SS-30M power supply and for some reason beyond me, Astron decided to use screw-down terminals to connect your radio DC cables. It is a small slotted screw and to me just a problem waiting to happen. My old Astron power supply had studs with nuts and made a very solid connection. There is a new version of the Astron SS-30 and it offers Anderson connections on the front. But the screw type connections are still present on the back of the supply.

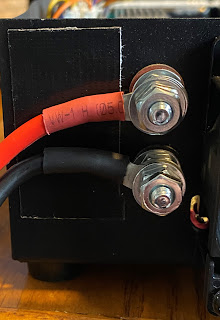

I decided it was time to do 2 things remove the inline automobile fuse holder and fuse on both the DC positive and negative radio cables supplied by Icom. It has been documented many times how these fuse holders have caused issues with voltage drop due to a poor connection over time. The other thing was a bit more ambitious which was to remove the screw-down positive and negative terminals on the Astron power supply. They were to be replaced with studs and nuts for a solid connection.

Old screw terminals

The Astron power supply is out of warranty as for sure doing this mod would certainly void the warranty. So lets get started....The screws fastening on the cover of the power supply are Torx-type screws and you will need the proper tool to get the cover off. Once the cover was off I removed the positive and negative cables from the back of the screw-type connectors. These 2 connectors were removed from the power supply and put in their proper place.....the garbage!

Out to the trash!

Two holes now had to be drilled in the case for the new studs and this is where success and disaster are a very fine line from one another. I placed tape on the inside and outside of the case as fewer filings from the drilling make their way into the power supply case. I also placed some protection on the inside of the power supply to also catch filings. I then marked off the holes and I used 3 drill bits to slowly move the hole up to the 3/8 size I was looking for. A word about the drill bits, I put a large amount of tape around the bit where I wanted it to stop once the hole was completed. No matter how good you are once that drill bit makes it way through the metal case it is going to want to keep going. You have a lot of pressure on that drill and well no one's reflexes are that good. I use the tape as a drill stop and it worked just fine as no damage was done to the parts in the power supply.

Drill bits

I used fibre inserts in the holes to insulate the studs from the case. These came from my other 20 amp Astron supply which are now on order from Astron. Then with the studs temporarily installed (no wires attached), I did a continuity check to ground and all was good, now the negative stud eventually does connect to ground and really does not matter but for poops and giggles I did it anyway.

I now connected the internal positive and negative wires to the studs and secured them. I then did the smoke test by turning on the power supply................all went well or this would be a much different blog post! I then tested the voltage at the Astron power supply new stud terminals and it was 13.86 VDC, then the cover when back on. I then added ring terminals to the Icom power cables (less the inline fuses and more on that in another post)

|

| Marked and ready to go |

When I powered the Icom radio up and looked at the onboard voltage meter was reading 13.6 volts DC and during transmit using an FT8 carrier (into a dummy load) the voltage only dropped to 13.12 volts DC which is a great improvement.

|

| Finish product |

K9YC & N0AX advise to NOT bond the 13.6 VDC negative lead to chassis ground. In fact, they recommend separating them in power supplies so designed. Separating them helps keep RFI out of the supply/radio and still is safe as the chassis should be bonded to the shack safety ground, not just through the AC cord.

Many hams will tell you not to worry about this. Many, many hams are wrong about a lot of things!

I had to replace my in-line fuses for the IC-7610 Icom and DX Engineering generously donated and I won at the 2019 Dayton Contest Dinner.

73, Bill Mader, K8TE

I was having the same problem with my 7300 and thought it was a radio problem. Alas, it was a power supply problem. Mine is more serious than just bad connections, mine is a bad regulator in the power supply. I had a spare power supply and now have another project sitting on the shelf. (Insert face slapping emoji here)

Good evening Bill, yes you are very correct and Ward Silver I have his book on grounding and bonding. I can see the way I wrote that part in the post can be misread. Once both connections (positive and negative) were connected the ohm meter would then be reading through the power supply. I do have another Astron power supply the RS-20M. I removed the direct connection to case ground on the negative post.

That is a great radio to win, I bet you were shocked when you found out you had won it.

73 and have a great weekend,

Mike

VE9KK

Good evening Steve very nice to hear from you, good news that you have a spare power supply. My RS-20M had the bridge rectifier go and I had to replace it and for me at the time I had no spare power supply.

Good to hear from you Steve and have a good weekend,

73

Mike

VE9KK

Another way to mark a drills depth is to use a metal or plastic tube or a short block of small section wood as a gauge.

73

Peter ZL1PWD

Good morning Peter, very good suggestions and I am sure one of those suggestion will pop to mind during another project of mine.

73,

Mike

VE9KK

Amateurs have always been better off by building their own equipment from scratch.

Good afternoon Bill, yes in a perfect world that would be great. A world where we had the time, parts were easily available and shipping costs were not out of this world. I had to get a part for my other power supply last year and it was performing a miracle to just find it and get it shipped.

Have a great weekend Bill and thanks for stopping by,

73

Mike

VE9KK

I replaced these connectors in my SS-30M with a cinch jones connector, a favorite of mine for many years. Cinch Jones were around decades before Anderson powerpoles. I can quickly unplug my radio from the power supply and plug it into my emergency battery supply. I’ve been collecting cinch jones connectors at hamfests for years, and they’re still available from suppliers.

Good morning Jack and thanks for taking the time to read and post a comment. I have seen on many occasions the Cinch Jones connectors at Ham fests but never thought anything of it. Seems like a more simpler way of connecting power cables. Thanks for the input and have a good week.

73,

Mike

VE9KK

Good morning all,

More substantial termination and connections are always good. If you have compression type terminal strips the use of ferrule termination when using stranded wire will help as well.

In this discussion, the length of power cable did not seem to be mentioned, but keeping leads short will also help.

One additional item is consideration of use of power supplies with remote sensing. Some of the last Heathkit linear power supplies had this feature and it is very common on commercial power supplies. There are two additional wires (sense + and -) that are used to provide voltage detection at the load instead of the source. Some power supplies can be adapted to add remote sensing.

Removing fusing is a tough choice since fusing is designed to protect the wiring from shorts. The choice does depend upon what over current features are available in the power supply and what those levels are relative to the wire size used and loads applied.

Over voltage is the other item to protect against. In linear supplies this is a real issue if a crowbar circuit capable of handling power supply full current is not present. Back in the 80’s, there was a product line of linear supplies who’s crowbar circuit PCB traces acted like fuses and opened up defeating the crowbar circuit and guarantying downstream failure of equipment.

Just food for thought.Bottom line is to remember to make sure you are protected from cascading failures.

73

Richard

KD5URB

Richard thanks very much for adding this valuable information. Some very excellent points to think about and look into. I for one am going to be looking further at your point about remote sensing.

Thanks again for taking the time to bring these point out to the group.

73,

Mike

VE9KK

Some additional items for consideration, Mike,

Fuses and fuse blocks vary significantly in quality and ratings.

When one encounters loose fitting fuses, don’t let the fuse escape your scrutiny. The fuse holder is only 1/2 of the connector. With the older 3AG fuses, checking the fuse required twisting the caps in opposite directions and making sure the fuse clips were tight and held tension. I’m sure most of us past the age of 30 have seen intermittent 3AG fuses or bad joint in the fuse cap.

With molded inline blade fuses, the issue is a little more complex. When removing a fuse that has been in service, you should expect to have to exert some effort to remove the fuse and to see bright metal were the fuse contacted the fuse holder.

Lack of either could imply a fuse or fuse holder issue. There have been a few fuse recalls in the past 10 years so never assume the fuse is correct. I have seen a few fuses with insufficient blade thickness, incorrect links for rated current, etc. Fortunately most of these subpar fuses appear to be off the market now but do watch out for too good to be true pricing because it is.

The other item is the fuse holder, some can be carefully retensioned by closing the opening for the blade from the fuse but you need to ask some additional questions.

Is the fuse holder discolored in the area of the fuse clips? Is the encapsulation discolored? It is likely that once the metal fuse clip material has been temperature cycled, than metal in the clip may loose temper and become soft. Don’t see this much where the correct fuse holder and wire size are in use but it can happen. Usually is a bad wire crimp and fuse holder should be replaced.

Removing a fuse from a harness is a bold move and should only be done when there is other protecting that is accurately set for the application. Most power supplies with either fold back current or trip off when overloaded but if that occurs at 35 Amperes in a 12 Ampere circuit you may enter the area of failure.

Likewise the TEN-TEC and some other top of the line transceivers have brute force protection built in to protect the transceiver. While the brute force (usually large zener) will protect the transceiver, if the protection device has to sink all the power supply current without and intermediate fuse sized for the transceiver, the zener will likely short and the transceiver will have to be repaired. If lucky you will get by without any printed circuit board damage. I have two mobile transceivers that were donated to the cause because the Power Amplifier (PA) transistor failed shorted and opened up the PCB trace from the power supply harness to the

Several companies are selling inexpensive high current fuses holders now and you can purchase fuses with LEDs in them to indicate failure if you are so inclined. In an emergency this may save trouble shooting time. This is one of those cases where a recognizable manufacture name is a good thing.

Summary is to remember equipment is designed to expect a certain level of external protection (fuses in this case) and removing inline fuses can exposed equipment to additional damage when an issue occurs. In any system, a power distribution scheme with proper protection elements should be maintained. Proper sizing of fuses and fuse holders with related wiring is essential.

Protection can consist of crowbar devices (over voltage), over current limiting, correctly size wiring and polarized connectors.

Every connection is a potential current limiting device and should be periodically checked. Power supplies should be checked for regulation and noise (especially switchers).

My apologies for the long note, but power issues are often overlooked when troubleshooting issues in many fields and fuse holders are part of the power circuit.

73

Richard

KD5URB

Good morning Richard and no need at all to send apologies for a long post. It contained great information that was well thought out. Thanks for taking the time to post it. A very good point when mentioning the connector the inline fuse slips into. In my case it is a stake on type setup. I found crimping (using needle nose pliers) the connecting gap on the stake on connector did the trick but the solid connection did not last. Ideally what I was looking for was a pair of Bussman clip type fuse holders along with some quality Bussman fuses. The Bussman holder has a solid screw type connection with a lock washer for the wire stake on to connect too. Also the connection between fuse and holder has a solid snap to it. I am still considering going down that road as well.

Have a great weekend Richard,

73,

Mike

VE9KK