Author Archive

Modernizing the DY-88 Power Supply

Modernizing the DY-88 Power Supply

Go with a Modern Vibe

Turning low voltage to high voltage

Bad Vibrations

Solid State

Note

. . . The pins are numbered 1 to 7, pin 1 is the large diameter pin on the right, and pins are counted clockwise from that pin. . . .

Results

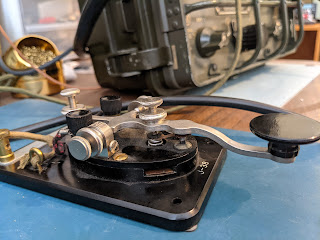

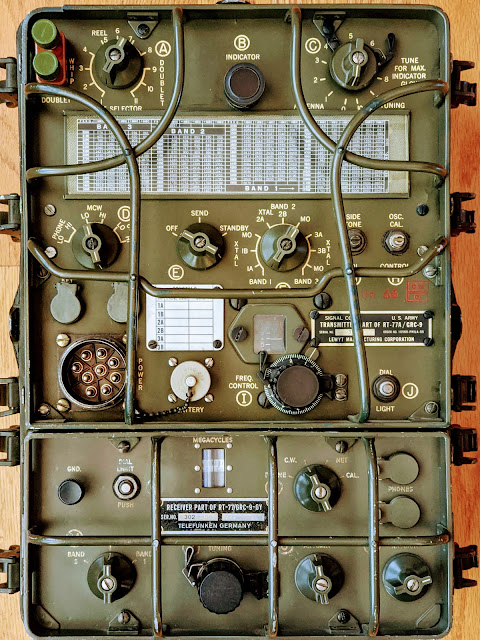

AN/GRC-9 aka “Angry Nine”

AN/GRC-9 aka “Angry Nine”

AN/GRC-9 - Long lived military comms

|

| My lovely (and radioactive) RT/77-GRC/9 |

|

| Hot receiver, in more ways than one |

|

| Out of the case, tracing a low B+ power problem |

Power on the move

- Transmitter Plates -- 475 - 580 v @ 100ma

- Transmitter Filaments -- 6.5 - 6.6 v@ 2 amps

- Receiver Plates -- 105 - 120 v @ 45ma

- Receiver Filaments -- 1.35 - 1.5 v @ 500ma

- Keying Relay -- 6.0 - 6.9 v @ 575ma

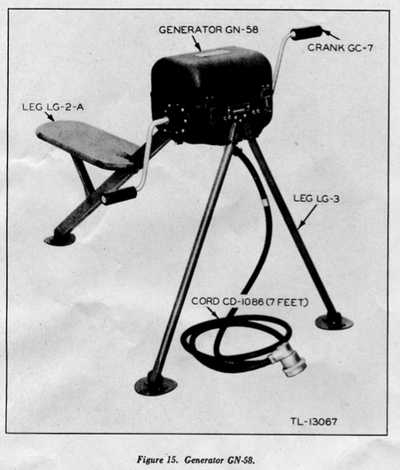

That's a tall order for mobile and portable power supplies but designers in the 1940's were quite clever in packing power supply units. I managed to obtain both the hand cranked GN-58 generator with the base chassis and seat for portable operations, and a DY-88 for fixed / mobile operations.

DY-88 mobile power supply

| DY-88 set to 12v powered by Amateur 12v supply |

|

| Vibrator power supply for low B+ |

|

| Power filtering |

I supply the DY-88 from either an RV battery or an amateur 12v power supply. When in Standby the DY-88 draws less than 1 amp, but placing the radio in Send mode switches on the Dynamotor which draws 12 amps @12v, without key-down and up to 14 amps on high-output key-down. It will drain an RV battery pretty quickly at that rate if the radio is left in Send mode, and works an amateur power supply pretty hard as well. So don't expect to operate remote off a battery alone for too long if your having lengthy QSOs. An added benefit of the DY-88 is that when the enclosed Dynamotor is running you'll have a nice extra 85 dB of generator noise to accompany your listening pleasure.

GN-58 portable field hand-cranked power supply

|

| Generator head in carry bag |

|

| NOS Shiny |

|

| Deployed |

If you have a BC-48 battery hooked up then your human power supply can pause cranking while your receiving. I have a BC-48 battery enclosure that has been gutted of the original, long-dead material and replaced with 10x 9v batteries in series for the low B+ and two D-Cell batteries in parallel for the receiver filament supply.

Accessories

|

| Bag of goodies |

Headphones

|

| Homebuilt CW filter with impedance switch |

Speaker

Antennas

Spares

More to come

|

| 50 kHz spacing when reading the frequency on the receiver Note the 7.2 is 7.200 MHz in the 40m band |

Images

Notes

Instructions for restoring a vibrator to operation

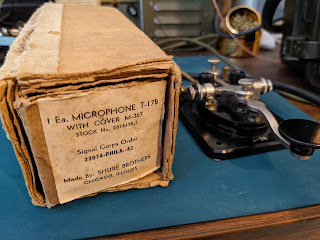

Hallicrafters HA-1 Electronic Keyer

Hallicrafters HA-1 Electronic Keyer

High Voltage Electronic Keyer from 1960

What an electronic keyer was like 60 years ago

A keyer without DIT / DAH memory

That really calls for a change in my paddle usage. My brain needs to keep in mind the length of DAHs so that I don't rush and release a following DIT before the current element completes. This is a bigger problem below 25wpm given the longer length of the DAHs.

The Hallicrafters HA-1 manual states that the keyer is different from other electronic keyers and requires "a knack" to use effectively. I think I've discovered whereof it speaks.

Conclusion

Space in Morse Code

Space in Morse Code

Silence is Beautiful

Proper Space (Timing)

Space between DITS and DAHS in a Character

Space between characters within a Word

Space between Words

How to Practice

When I hear break-in occur between every word I know that I'm putting in a good minimum amount of spacing

Conclusion

DE AA4OO

Regulated voltage for Regenerative receiver project

Regulated voltage for Regenerative receiver project

Mr. Regula-tor

Fortunately, the regen circuit uses a ridiculously small amount of current for B+; about 4 to 5mA. Although I will likely change the audio side of the tube to deliver enough current for a speaker rather than the high impedance headphones in the current design, which may potentially double that to 10ma. For the first incarnation I'll stick with high-impedance headphones.

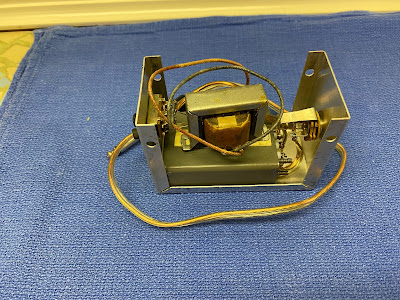

Generally batteries are used with regenerative receivers because they are so sensitive to power supply noise, but I wanted to give the power supply a shot first and if it proves too noisy I can fall back to battery power for the B+ and just use the filament voltage provided by this transformer.

Since I have a OB2 voltage regulation tube I want to use. The OB2 regulates at 108V so that's what I'm going with. An OB3 would regulate at 90V, but I don't have one of those.

|

| OB2 in action... Glow baby, Glow! |

Calculating the resistor drop

Rdrop = (Vs - Vreg) / (Ireg + Isupply)So, in my case:

Voltage supply (Vs) = 189V

voltage regulation (Vreg) = 108V

regulator current (Ireg) the OB2 requires 5mA to do its job = 5mA

supply current (Isupply) the actual current required by the 6SN7 up to ~ 5mA

So, (189V - 108V) / (0.005A + 0.005A) comes out to a resistor value of 10,100 ohms. 10k is the closest standard size resistor and at 108V it should be able to dissipate 1.166 watts. So I'll need a 10k 2-watt resistor.

Parts is parts

Summary

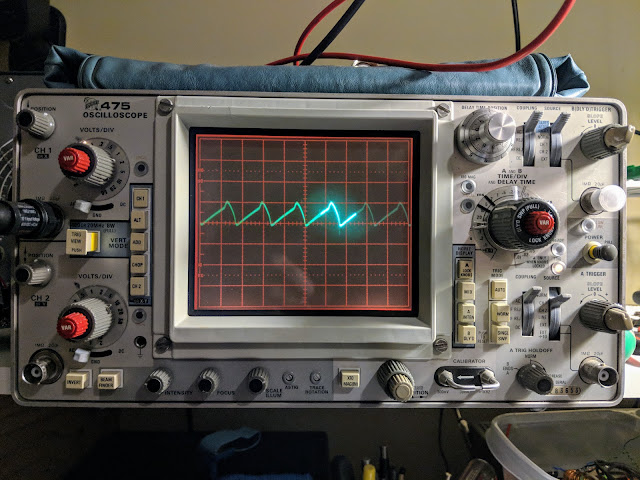

With the current values I'm seeing 50mA ripple on my regulated voltage.

|

| A bit over 50mA ripple |

That's all for now....

So lower your power the old fashioned way, using a voltage regulator tube.

72/73

Richard, AA4OO

Heathkit Art

Heathkit Art

Heathkit HP-23A and IM-11

Metering High Voltage on the cheap

Metering High Voltage on the cheap

🗲 Heathkit VTM model IM-11 🗲

So what did hams of yesteryear use?

Behold... Vacuum Tube Volt Meter

Vacuum Tube Volt Meter

This Heathkit VTVM model IM-11 was available at my local Hamfest (Rarsfest) for 5 dollars.Debugging

The 55 year old 16uFd@150V paper, electrolytic power filter capacitor was likely a ticking time bomb so I replaced it with a modern capacitor for safety concerns. The closest one I had was a 33uFd@160V radial electrolytic. I don't think double the capacitance will be a problem for a filter capacitor, it will just make the transformer work a little harder when it's first turned on. I calculated the initial charge time and it's 393ms vs 190ms for the original cap. I think the 10k resistor and transformer can handle the extra 200ms heavy load on power up.

A few wires inside the meter had come loose from some very sparse solder points and a one intermittent connection in the range switch was especially troublesome to track down.

The biggest mystery to solve was oversensitive resistance readings in the Ohms mode. I replaced the C-cell battery in the battery cup and while I had it out I glanced at the + connection for the battery in the cup. I appeared to have oxidized at some point in the past and was discolored. I scraped it off until I saw shiny bits and thought all was good. I spent more time tracing the circuit and thought I had a problem with the switch itself or the 9x resistors in the range circuit, as suggested in the troubleshooting section of the manual. The problem turned out to be that oxidized bolt head that formed the positive battery connection in the battery cup. Scraping it had not provided electrical contact. In fact, when I removed the bolt (after having to disassemble the circuit board from the meter for the 2nd time), I filed down the head of the bolt and could find no conductive metal left. I'm guessing that a former leaky battery had converted the entire head of the bolt to a very hard, yet non-conductive material. I've never seen anything like it before and it proved to be a useful lesson.

I had to find a replacement bolt and that lead to working on my lawn mower and then mowing the yard... not sure how that progression occurred... Eventually I got the new bolt in the cup, the circuit board re-installed. Ohms tested accurately, put it all back together and noticed the #50 pilot lamp had stopped working (sigh). I removed the innards from the case one more time and got the pilot bulb settled (I think it's required to balance the filament circuit). While I had it apart for the umpteenth time, I decided to reconnect the 1/4" plug that a former owner had disconnected while keeping their original modification allowing 1 mega-ohm to be switched in for the outermost probe when DC functions are selected but switched out when AC or Ohm functions are chosen. I wanted to allow use of an original VTVM probe used in the 1/4" plug with its built-in 1 mega-ohm resistor.

Whew!

All-in-all, I probably spent 8 hours getting all the functions on my $5.00 meter to work, replacing old parts, undoing mods and aligning it for proper DC and AC readings. It's a good thing I don't count my time in the cost of these projects, otherwise I could have purchased a couple Fluke meters for the cost of my time.

What's the fun in buying something that works right the first time when you get it home, huh? Are we hams, capable of solving problems, or appliance users? Actually, it would have been nice if it worked without new parts and repairs, but I digress.

Back to the story

This meter can measure up to 1500 Volts 🗲

Although this meter uses a C-cell battery for measuring resistance, it runs off service mains to power the tubes which control the meter circuitry, so it must be plugged in to be used.

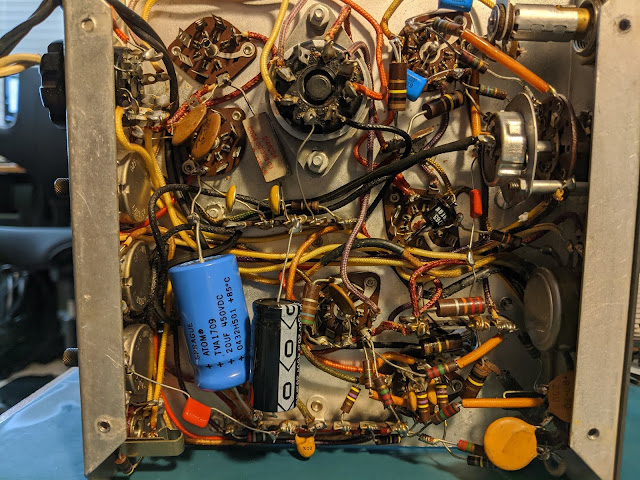

Wiring, lots of wiring

|

| Point to point wiring makes for interesting circuit tracing |

Shiver me timbers, it's got decks

It also refers to "front half" and "rear half". The "half" is referring to a side of the deck, so in the case of "front half" it refers to the side of a particular deck facing the front of the instrument, while the "rear half" is the side of a deck facing back (or toward you).

|

| Clever voltage divider circuitry, what could possibly go wrong in this triple stack of wafer switches? |

A knob for every function and a function for every knob. NOTE: do not plug your headphones into the 1/4" jack on the front unless you want to experiment with personal electro-shock therapy. Better, yet, don't plug your headphones in there.

|

| Not clearly shown in this photo, voltage divisions up to 1500 volts supported |

"...Weighed in the scales and found wanting"

Summary

Dazzle your friends next time they ask you to measure something for them, by whipping this not-so-little-puppy out of your back pocket and powering it up. As you're making your measurements quietly repeat "Mmmm, yes. Mmmm yes, I see now". They'll have no idea what you're referring to and be quite impressed.