Posts Tagged ‘New Carolina Windom’

Today’s QSO with KØLR, Who Gave Me My Novice Code Test in 1978

Today’s QSO with KØLR, Who Gave Me My Novice Code Test in 1978

My online ARRL course, “Introduction to Emergency Communication,” is in full swing. I’m happy to say that it is pretty demanding. Not that the material itself has been especially difficult (yet), but the essay-assignments do require some thought — and other assignments are pushing me to do some new things on the air, like listening to several nets, critiquing an NCS (Net Control Station), and checking into a net (okay, I probably have checked into a net or two over the years, but it’s been so long that I hardly remember doing it).

Today I reaped some unexpected benefits from one of these assignments. Having been assigned to check into a formal net, I checked into the PICONET this morning. This was no small feat, since it was on 75 meters. My New Carolina Windom is only cut for 40 meters, and the automatic tuner on my Kenwood TS-440S has never been able to match it — the SWR is terrible! But using my old Drake MN-7 Matching Network, I was able to match it surprisingly well. So now I’m on 80/75 meters! I even made a CW contact with a fellow in Wisconsin, and got a decent signal report.

And after checking in this morning, I visited the PICONET website — and learned that Lyle Koehler, KØLR, would be the NCS for the PICONET this afternoon! Wow! Lyle is the ham who gave me my Novice code test back in 1978. I was only 10 years old, but I remember it like it was yesterday. I’ll never forget how I shook like a leaf on the couch in his living room while he sat beside me and tapped out 5 wpm code with a straight key and oscillator. When he told me I passed, I couldn’t wipe the grin off my face for the rest of the day!

So the thought of talking with Lyle again after all these years was enough to make me watch the clock, eager for the PICONET to open again at 1500 CDT. And sure enough, at the appointed hour I heard Lyle’s voice as he opened the net! I was his first check-in, and I took advantage of the net’s slow start to explain that he had given me my Novice code test over three decades ago. He remembered me!

What a pleasure to meet this fellow on the air after all these years.

Lessons Learned During Antenna Construction

Lessons Learned During Antenna Construction

I learned a few lessons — the hard way — while building this New Carolina Windom. At risk of making myself look like an idiot I’ll share some of them with you here so that you can learn from my mistakes.

You might wonder how a guy who has been a ham for 33 years could be so ignorant about some of these things, but understand that up until this project I had never even put up an outdoor antenna on my own. My dad was the one who did all this when I was a kid. When I became a homeowner, all my antennas were indoor, stealthy antennas located in my attic — a whole different ballgame. That doesn’t work in my current house, so for the first time I’ve had to build up an outdoor antenna-system.

Anyhow, here they are (in no particular order):

- Drilling holes in masts: Use a titanium bit. It’s worth the money! I used lesser bits at first, to my frustration. Titanium bits cut through aluminum like a hot knife through soft butter, and they make short work of steel, too. If you’re drilling anywhere but in a workshop, make sure you put down newspaper or something to catch the metal shavings; metal shavings do not contribute to a “barefoot lawn!” Also, build a good jig if you’re drilling all the way through the mast. The jig I built did a good job of holding the mast in place but next time I’ll improve it with a guide that ensures top-dead-center and (in lieu of a drill-press) perfectly perpendicular drilling.

- Cutting & handling antenna wire: Be generous when cutting the legs of your antenna. I thought I was generous, but when it came time to make my final adjustment (after SWR testing) I could have used just a few more inches than the extra 15″ I had allowed myself on the long leg of my New Carolina Windom. And when handling 14 AWG copperweld, watch out for kinks! As hard as I tried, I came mighty close more than once to putting a bad kink in that unwieldy stuff.

- Erecting masts: Use a level to make sure the mast is vertical. I know, DUH! I did use a level when I put the tripods up, but when it came time to put the masts in I had forgotten to bring it up on the roof with me. It was just too tempting to pop them in without checking to see that they were perfectly vertical. I found out the hard way that a mast can be tilted quite a bit and still look perfect when peering up its length!

- Working safely on the roof: Use a safety-line. The first time I went up on my roof I was surprised at how much steeper it was than the one I used to scramble around as a kid. Frankly I was scared stiff up there, especially with this bum leg of mine. I’ve heard there are safety harnesses out there, but I couldn’t find one. So what I did was to throw a safety-line over the roof and tie it off to something stout. That at least gave me some added security on the side of the roof opposite the attach-point. Just make sure your rope is strong and your knots are good!

- Soldering wire on the roof: Buy or borrow a butane soldering iron. I found out the hard way that even a 100 watt soldering gun is useless at the end of a long extension cord. It worked fine for soldering lugs onto the end of my 14 AWG copperweld, but not for soldering the same wire twisted onto itself. And a regular propane torch is definitely not the right tool for the job (I know, I tried!). Also, you might want a drop-cloth up there. By the time I was done with the job using a propane torch (you should have seen it — it was pretty comical), I had more than one solder-drip on the shingles.

- Waterproofing coaxial connectors: Use coax-seal or self-amalgamating tape. As I mentioned in my earlier post on this subject, I at first just used electrical tape to wrap my coaxial connectors. After being persuaded by several kind hams who posted comments on that post, I ordered some coax-seal. It’s a good thing I did; I am grateful to those hams for their good advice. When the shipment arrived, I went up on the roof to discover one of my nice pretty tape-jobs already coming apart at the seams after less than two weeks! By the way I found out that five feet of 1/2″ coax-seal is good for only three connections, at least the way I wrapped them.

- Using pulleys: Use big enough rope. The first time I hoisted my antenna the rope was too small; it quickly jumped off the pulley and got jammed between the pulley and the housing. Fortunately I got it free. I swapped out the thin rope for something much stouter, and now it will never get stuck. (By the way, I’ve read one ham’s advice not to use pulleys at all but ceramic egg-insulators instead; there’s nothing for the rope to get stuck on and they’re durable enough that he’s been using one as a pulley for 20 years.)

- Allowing for radials: Build in an attach-point for radials at the base of your RF choke if you’re building a New Carolina Windom. Only after my antenna was complete did I read about the benefits of adding radials to this antenna. There is no good way that I can think of for me to connect radials directly to the coaxial connection. Next time I build an RF choke I’ll provide some lugs (or a plate or something) on one end for this purpose.

- Testing SWR: Make sure you hoist your antenna all the way up before testing its performance. I tried testing my antenna before climbing up on the roof — my son held the mast upright and I tied the legs of the antenna off as high as I could to nearby trees, but the SWR was just too high on 40 meters due to the proximity of the antenna to the ground.

- Throwing lines: If you have trouble throwing a line, try a heavier weight at the end. I now know that throwing lines is an art. At various points in this project I experimented with a sling-shot, potato-gun, and throwing by hand. Each of these techniques has its place. At one point the best way for us to get a line where we wanted it to go was by simply whirling a weight and letting it fly — but only after we figured out that we needed a good heavy weight at the end. At first I used just a few ounces of metal, but it kept getting hung up in the branches we were penetrating. Once we switched to a pop bottle full of water, it worked on the first try.

- Pounding ground rods: Put your connectors on the ground rod before pounding it all the way in, if they’re the kind of connectors you have to slip on over the top of the ground rod. By the time I was done pounding in my 8-foot ground rod, the top was so flattened out I couldn’t get the one-piece connector over the top. (An angle-grinder solved the problem; I cut off the top and slipped the connector on.)

No doubt some of these lessons I’ve only partially learned (and maybe some of them I haven’t learned well at all). If you have any better suggestions, or if you have some of your own hard-won lessons you’d like to add, fire away. If we can learn from each other here, maybe we won’t have to learn quite as many lessons the hard way!

Estonia on 30m, and Antenna-Days 3-5 in My Son’s Words

Estonia on 30m, and Antenna-Days 3-5 in My Son’s Words

This antenna works great! In my earlier post I mentioned that SWR was high on 30m, but last night I let the automatic tuner on the TS-440S match it — and ES3AX gave me a 579 from Estonia! 4Z5MU (Israel) went into the logbook last night, too, but that was on 20m.

A couple weeks ago I published my son’s take on Antenna-Days #1 and #2. Here is his take on the rest of the project:

Helping Dad Build His Antenna, Days 3-5

by Antonio Mitchell, October 20, 2011Building the antenna has taken a bit. It has been fun for the most part. We finally have it almost finished. The past couple days have been really busy. I hope that I can remember them so that I may provide my readers with an understanding of what we did.

It was pretty chilly on Monday. The wind was blowing pretty hard so we did not get to go on the roof. We spent the day getting the antenna wire cut and put onto the balun. Once we were done with putting the antenna wire on the balun my dad had to put it on to the pulley attached to the aluminum pole. My dad and I put the pole against the house and took the two ends of the antenna wire and tied ropes to them. After that we took the ropes and tied them to some trees. It was so windy that it was hard to hold the pole. While I was holding the pole my dad took the SWR meter and tried to figure out if he needed to add or take away some wire from the connectors on the balun. It did not work so well. [Being so close to the ground, SWR was sky-high on 40m.] We took the pole and the ropes down and called it a day.

On Tuesday we first shot a weight over the house so that we could get a safety line over the house. The safety line was for when Dad went on the roof. It took us quite a few tries to get it over the house. Once the line was over we attempted to put a line over the tree which is where one end of the antenna wire is going to sit. Using my slingshot did not work. My dad went up to Runnings to get ground wire and PVC pipe to build a potato launcher. It took him a little while to find all of it. When he came home we assembled the potato launcher. After supper we tried to get a line over the tree, but it was dark and windy. We did launch a potato with a screw in it. It did not go over the tree because of the wind. It went over a couple trees. We could not find the potato.

Wednesday we did manage to find the potato. We had to cut some of the line we used. My dad decided he would get the line into the tree when he was on the roof. A friend of my dad came over and helped put the aluminum pole with the antenna attached and the other pole into the tripods. The antenna is finally up! My dad just has a few final touches to do and then it will be up there for good I hope. Last night my dad was able to talk to some people on the air using the antenna that is now on the roof.

Update on New Carolina Windom

Update on New Carolina Windom

Well, it’s almost done! The antenna is in place, optimized, and operational. Last night my son helped me finalize the connections at the ground rod and string the coax and ground wire into the house. There are only a couple of details to take care of before winter sets in, but they shouldn’t take much time — I hope to be done with them by next Monday’s end if not sooner. I hope to find time soon to write up some of the lessons I learned.

I couldn’t have done it without the help of my son Antonio and my friend Dale (“half squirrel, half monkey”), not to mention the encouragement my wife kept giving me. My son was my constant companion, “go-fer,” and an indispensible helper on many tasks. And Dale might have saved my life since I’ve no business being on the roof with a bum leg. He did the lion’s share of the work up there the day we put up the masts and the antenna. He’s so good on a roof I think he could have run laps around the perimeter, while I clung for dear life to a safety line when getting on and off the ladder.

SWR is below 2:1 across all of 40m, 20m, 17m and 10m (except for the first 100 KHz of 10m, but even there it’s still below 3:1). It’s high on 30m, 15m, and 12m, but I’ve read that this can be improved by running radials from the bottom of the RF choke. I’ll let you know how that works.

Last night I made one contact after tidying up the connections in the shack: TX7M, a DXpedition in the Marquesas Islands, French Polynesia. That was a first for me, working a DXpedition. It was decidedly unsatisfying — the ultimate antithesis of a ragchew with a worthless signal report (just a recorded “599″ that goes to everybody, regardless of their true readability, strength, and tone). But it was still encouraging, especially since it was on 17m, a band I’ve never even touched before I built this antenna.

Free! Excel Worksheet for Building Any 1/2 Wave Dipole (Center-Fed, OCF, Windom, New Carolina Windom)

Free! Excel Worksheet for Building Any 1/2 Wave Dipole (Center-Fed, OCF, Windom, New Carolina Windom)

Here is a spreadsheet I designed in Microsoft Excel for calculating the first cut and the final cut (after testing) of a 1/2 wave dipole, whether center-fed, classic off-center-fed, Windom, or New Carolina Windom. If you use it for a plain ol’ center-fed dipole, just ignore the references to “long leg” and “short leg” — the numbers will still be right. Anyhow, you’re welcome to use it, pass it around, whatever:

DipoleWorksheet.xls (Microsoft Excel)

I’d enjoy hearing from any of you who end up using this spreadsheet to build an antenna!

If you find any bugs in this spreadsheet, please let me know. Note that it is protected for your convenience, but you can unprotect it anytime you like to see the formulas in each cell (there is no password).

What’s the Best Way to Hang an Inverted-V OCFD/Windom Antenna?

What’s the Best Way to Hang an Inverted-V OCFD/Windom Antenna?

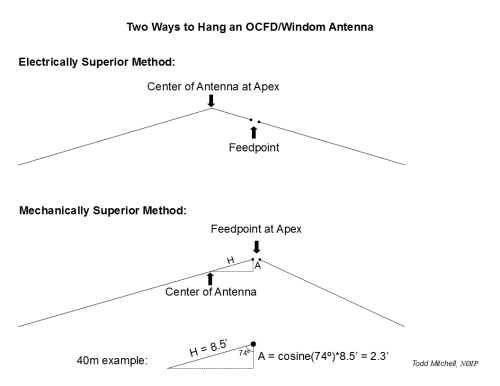

What is the best way to hang an off-center-fed dipole or windom antenna as an inverted-V? Should you hang the feedpoint at the apex, or hang the center of the antenna at the apex?

From an electrical standpoint the best way is to hang the center at the apex. That is where the current is at a maximum on the lowest resonant frequency. But that leaves all the weight of your balun, coax, and (in the case of a New Carolina Windom) RF choke unsupported by anything but the antenna-wire itself. So from a mechanical standpoint the best way is to hang the feedpoint at the apex, with all that weight hanging straight down from the hanger. Either way it’s a trade-off.

I think it makes sense to hang the feedpoint at the apex if the angle of your V is reasonably broad. The mechanical benefit outweighs the electrical cost in this case. As you can see in this diagram, you really don’t give up much height at the center of the antenna. My own 40m New Carolina Windom, with the longest leg at 74o from vertical, sacrifices only 2.3′ at the center of the antenna. Even if it were cut for 80m the sacrifice would only be 4.5′. A 160m version (I know of one fellow who plans to build one!) would give up almost 9 feet, though. You might want to hang the center at the apex in that case, unless it’s already so high that 9 feet doesn’t matter much. You can always figure out a way to support the feedpoint in some way if you need to.

This changes if you mount your V with a narrow angle. Dropping the longest leg to 45o from vertical would cost me 6′ on my 40m New Carolina Windom! In that case it would probably make more sense to hang the center at the apex.

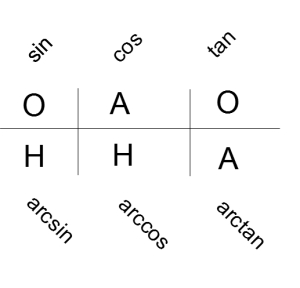

The way to calculate this is shown in the figure above. Notice how I labeled the sides of that triangle with “H” and “A?” Now why did I do that? Glad you asked! The “H” stands for “hypotenuse” and the “A” stands for “adjacent” — adjacent to the angle of 74o in this triangle (your own angle may be different, of course). Just remember this sentence: “Oscar And Ole Have Huge Appetites.” (Up here in Minnesota we all love that name Ole, don’t ya know!) That will help you remember the way to calculate the sine, cosine, tangent, arcsine, arccosine, and arctangent of any angle. “O” stand for opposite (the length of the side opposite the angle you’re dealing with), “A” stands for adjacent, and “H” stands for hypotenuse:

So to figure out the height of the apex above the center of my antenna, I figure:

A/H = cosine(74o)

A = cosine(74o)*H

A = 0.276*8.5′ = 2.3′

There you go! Of course, you’ll have to know the angle to figure this out. To see an example of that calculation, check out my previous post.

RF Choke

RF Choke

The New Carolina Windom uses part of the feedline as a vertical radiator — the voltage balun used to feed the off-center fed dipole allows common mode current to travel down the feedline. How do you determine how much of the feedline radiates? From what I’ve read, you do this by placing an RF choke (sometimes called a “line isolator”) at some point in the feedline to clamp off the common mode current. For an 80 meter version, you put the RF choke 20 feet below the feedpoint. For a 40 meter version (like I’m building), you put it 10 feet below the feedpoint.

To build my RF choke I followed the instructions provided by Len Carlson, K4IWL. In an addendum published here, Mr. Carlson wrote:

A note about the choke [between the balun and the feedline]: The choke [line-isolator] is simply a straight piece of coax with ferrite cores strung on it. Just use the same coax that you are using for the field line from the Xceiver to the choke. I have made a mod to the choke also. Instead of bending it back inside of the CPVC tube, make it a straight piece of coax about 0.3 meter. The length is not critical but should be no shorter than about 12 inches. Use as many ferrite tubes that will fit in-line on that length.

I built my RF choke using 12 FB-56 ferrite beads (mix 43) from Palomar Engineers strung on a piece of RG-58 coax and secured on each end with wire-ties. While Mr. Carlson chose CPVC for a lighter enclosure, I used PVC. In order for the SO-239 bulkhead-mount coax connectors to fit in the endcaps, I had to go with 1 1/4″ pipe. This did make for a pretty large enclosure — the beaded coax in the pipe does slop around a bit in there when shaken. If I have to do this all over again I’ll figure out some way to secure the innards of this thing (maybe by injecting some expanding foam?). As it was I inserted a few inches of double-sticky foam mounting tape inside the last end to be sealed, which did help somewhat.

I attached one end of the beaded coax directly to an SO-239 connector/end cap, but the other end required several inches of slack to stuff into the tube when it came time to push the final end-cap onto the pipe.

Here is a slideshow of my RF choke. After I took these photos I covered the coax connectors with cling-wrap and spray-painted the whole thing forest green.